Shop prehung fiberglass shed doors—ready-to-install units with frames, hinges, and weather stripping. A hassle-free upgrade perfect for DIY projects.

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

Prehung Doors

A prehung fiberglass door is a complete door system that comes already mounted in its frame with all hinges installed and properly aligned. The entire unit arrives ready to install directly into your shed's rough opening. This differs from a standard door slab, which would require you to separately purchase a frame, cut it to size, install hinges, and hang the door yourself. Our prehung doors include the fiberglass door panel, jambs (frame), weather stripping, and pre-installed hinges as a single unit. This integrated design eliminates the most technically challenging aspects of door installation, making it ideal for DIY projects and ensuring proper functionality from day one.

Measuring for a prehung door requires focusing on the rough opening in your shed wall, not the door itself. Start by measuring the width of your rough opening at three points: top, middle, and bottom. Then measure the height at three points: left side, center, and right side. Use the smallest measurements as your reference. Standard rough openings should be approximately 2-2.5 inches wider and 2-2.5 inches taller than the actual door size to accommodate the jamb and provide space for leveling and shimming during installation. For example, a 36"x80" door typically requires a rough opening of approximately 38.5"x82.5". If you're replacing an existing door, measure your current door size and consult our sizing chart to determine the appropriate prehung unit.

Installing a prehung fiberglass door requires basic tools that most homeowners already own. You'll need: a hammer, level (4-foot recommended), tape measure, utility knife, pry bar (if removing an old door), shims, screwdriver or drill with appropriate bits, caulking gun with exterior-grade caulk, and a square. Optional but helpful tools include a reciprocating saw (if modifications to the rough opening are needed), a chisel for minor adjustments, and a nail set for finishing nails. No specialized door-hanging tools are required, which is one of the main advantages of choosing a prehung system. Most installations can be completed by one person, though having an assistant to help hold the door while securing it can make the process easier and faster.

For most DIY enthusiasts with basic skills, installing a prehung fiberglass shed door typically takes between 1-3 hours, depending on your experience level and whether any modifications to the rough opening are needed. First-time installers may require closer to 3 hours, while those with previous experience can often complete the installation in under 90 minutes. The process includes: removing any existing door (15-30 minutes), preparing the rough opening (15-30 minutes), setting the prehung unit in place (10-15 minutes), leveling and securing the door (30-45 minutes), and applying finishing touches like exterior trim and caulking (15-30 minutes). Our comprehensive installation guide breaks down each step to ensure even novice DIYers can achieve professional results.

Fiberglass doors offer distinct advantages over both wood and steel for shed applications. Unlike wood doors, fiberglass won't warp, rot, or crack when exposed to moisture and temperature fluctuations—a common issue with outdoor structures. They're also highly resistant to insect damage. Compared to steel doors, fiberglass won't dent from impacts, rust in humid conditions, or transfer heat as readily, making them better insulators. Fiberglass doors are typically lighter than both wood and steel, making them easier to operate and putting less stress on hinges and frames. The material can be manufactured with realistic wood grain textures and accepts paint or stain beautifully, providing the aesthetic appeal of wood without the maintenance requirements. While fiberglass doors may have a higher upfront cost than basic wood options, their extended lifespan (often 15-25 years with minimal maintenance) and resistance to environmental damage make them more economical long-term.

Yes, our fiberglass shed doors can be both painted and stained to match your aesthetic preferences. The doors feature a textured surface that mimics real wood grain, allowing them to accept stain in a way that creates a remarkably realistic wood appearance. For painting, fiberglass requires specific preparation: clean the surface thoroughly, lightly sand with fine-grit sandpaper, apply a bonding primer designed for fiberglass surfaces, and finish with high-quality exterior latex or acrylic paint. For staining, we recommend using gel stains specifically formulated for fiberglass doors rather than traditional wood stains. These products create rich, wood-like tones without the need for wood's natural grain to absorb the color. We offer comprehensive finishing instructions with each door purchase, including recommended products and application techniques for optimal results and longevity.

Fiberglass doors require significantly less maintenance than wood or metal alternatives. The basic maintenance routine involves: cleaning the door surface 1-2 times annually with mild soap and water to remove dirt and debris; inspecting weatherstripping yearly and replacing if worn; lubricating hinges and hardware with silicone spray annually; and checking the caulking around the door frame every 1-2 years, replacing as needed. Unlike wood doors, fiberglass doesn't need regular sanding, refinishing, or sealing to prevent moisture damage. If painted or stained, fiberglass finishes typically last 5-7 years before requiring refreshing, compared to 2-3 years for wood doors. This minimal maintenance regimen helps ensure your fiberglass door maintains its appearance and functionality for decades while protecting your shed's contents from the elements.

Yes, prehung fiberglass doors offer excellent energy efficiency for climate-controlled sheds, workshops, or studio spaces. Fiberglass naturally provides better insulation than wood or steel due to its composite structure, which reduces thermal transfer. Our prehung units feature comprehensive weatherstripping systems already installed and properly aligned, creating an effective seal against air infiltration. Many models include built-in door sweeps to prevent drafts at the threshold. For maximum energy efficiency, we offer models with insulated cores that provide R-values up to R-15, significantly outperforming solid wood doors (typically R-2 to R-3). The pre-assembled nature of prehung doors ensures that the weathersealing components work together as a system, eliminating the gaps and alignment issues common with separately installed doors and frames. This makes them ideal for sheds that house temperature-sensitive equipment, serve as workshops, or require climate control for other purposes.

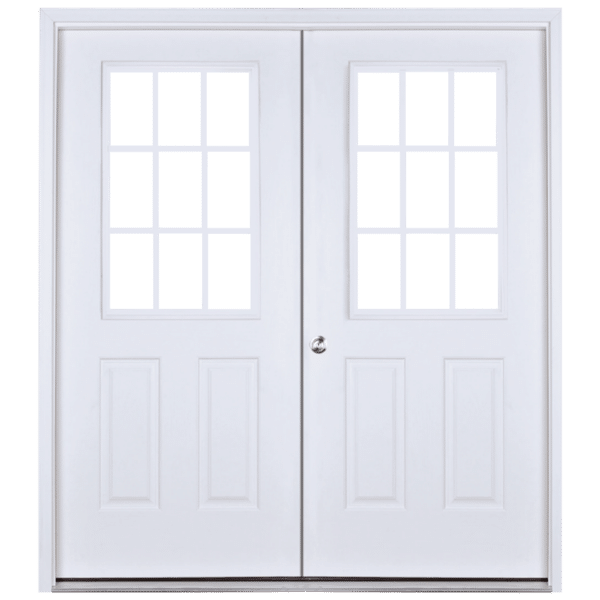

Yes, many of our fiberglass shed door models are available with integrated window options. We offer various window styles including half-lite, full-lite, craftsman grille patterns, and decorative glass options. These windows are factory-installed in the door, ensuring proper sealing and structural integrity. The windows feature double-glazed, tempered safety glass that provides both security and insulation benefits. For existing doors without windows, we do not recommend cutting openings as this can compromise the door's structural integrity and warranty. If adding natural light to your shed is a priority, we suggest selecting a door model with pre-installed windows during your initial purchase. For security concerns, our window options include frosted, obscure, and textured glass variations that admit light while maintaining privacy for your stored items.

Our prehung fiberglass shed doors accommodate a wide range of hardware options to meet your functional and aesthetic preferences. Standard options include lever handles, knob sets, deadbolts, and combination lock/handle sets in various finishes including brushed nickel, oil-rubbed bronze, matte black, and polished brass. All our doors come pre-drilled for standard 2-3/8" or 2-3/4" backsets, making hardware installation straightforward. For enhanced security, we offer reinforced strike plates and multi-point locking systems compatible with our door designs. Specialized options include keypad electronic locks, Bluetooth-enabled smart locks, and heavy-duty commercial-grade hardware for high-traffic or security-sensitive applications. All hardware can be installed with basic tools, and comprehensive installation instructions are included with each purchase. Custom drilling patterns for specialized hardware can be accommodated through our special order program.